-

SEM Series

-

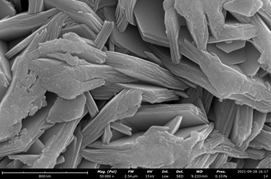

Semiconductor thin film measurementHard coating measurement

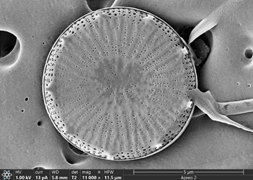

Field emission scanning electron microscopy (FE-SEM) has higher resolution compared to filament electron microscopy, with magnifications reaching up to the order of 100,000x. This places higher demands on the particle size of the sputtering instrument for gold deposition. Not only is it required that the particles be fine and not cover the sample surface, but there should also be gains in charge elimination and contrast enhancement.

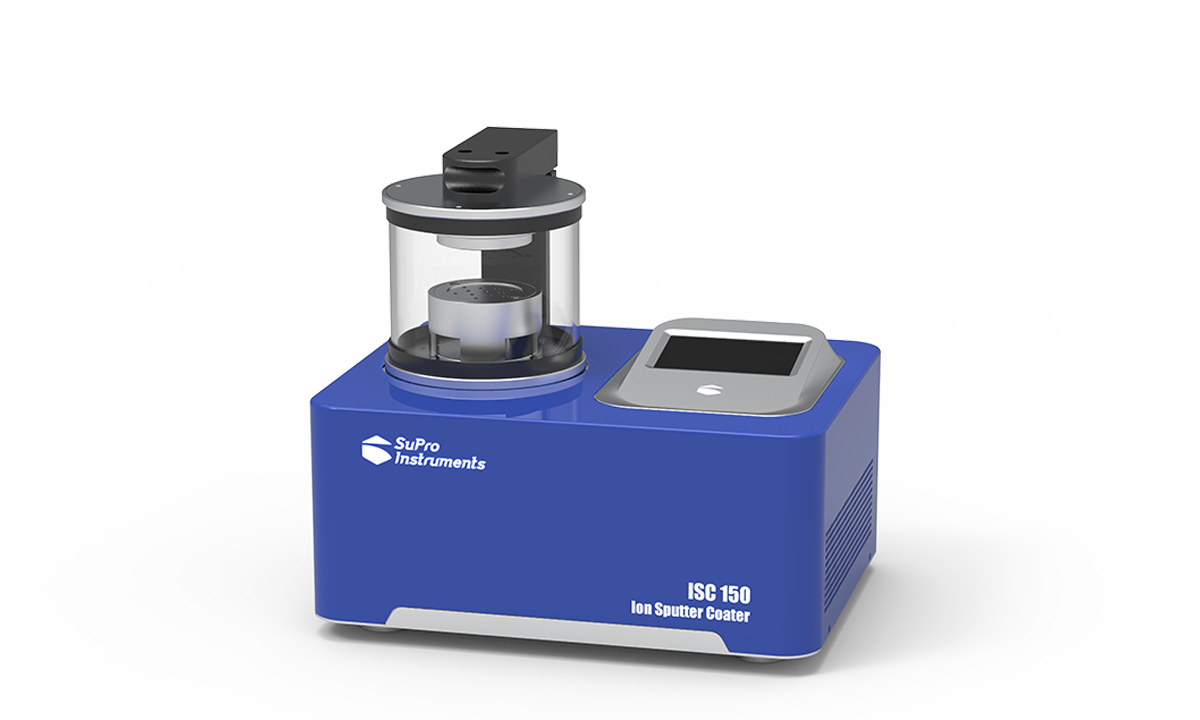

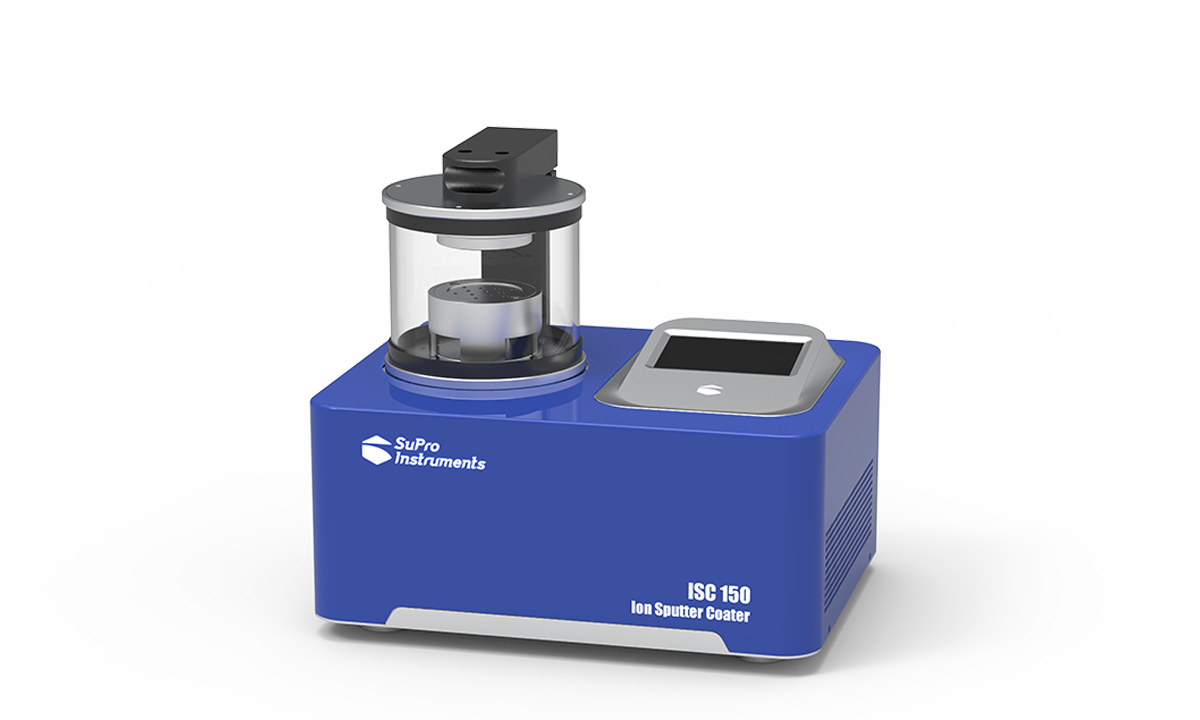

The standard approach for sample preparation in FE-SEM is sputter-coating with Pt metal, as the particle size of Pt is only 2-3 nm. The small particle size is advantageous for presenting a more realistic morphology of the sample. The ISC150 ion sputtering instrument can be equipped with a Pt target for sputter-coating samples for FE-SEM, which helps alleviate charging without masking the true morphology of the sample.

|

Technical Specifications |

parameters |

|

Vacuum Pump |

Rotary Vane Pump |

|

Pumping Speed |

≥4m3/h |

|

Ultimate Vacuum |

<1Pa |

|

Working Pressure |

4-10Pa(Constant Pressure Control ) |

|

Pumping Time |

<3-5Min |

|

Vacuum Gauge |

Pirani Vacuum Gauge |

|

Chamber |

Ø150*120mm Scratch-resistant Quartz Glass |

|

Sputtering Target |

Ø50*0.1-1mm |

|

Sputtering Power |

Constant Power Magnetron Sputtering DC Power Supply ( Max.20W, Max.100 mA, 0-800V DC ) |

|

Operation Mode |

Touchscreen Control with the Control System Providing Interlock Protection Functions |

|

Weight |

~20kg |

|

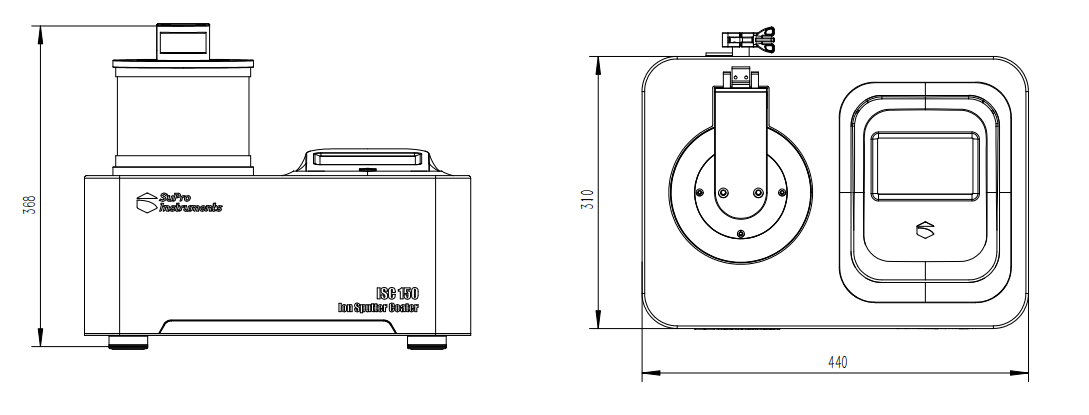

Dimension |

~400mm*337mm*346mm |

|

Power Supply |

100-220V AC, 50/60Hz Grounding Triangle Plug |

|

Power Consumption |

<500W |

|

Warranty |

One Year |