-

SEM Series

-

Semiconductor thin film measurementHard coating measurement

Ultra-high-resolution field emission SEM can achieve magnifications in the range of 200K to 300K times, thus demanding finer granularity in metal coating.

Standard Pt or Pt-Pd alloy solutions can no longer meet these requirements well. Higher melting point Ir targets are too expensive, so high melting point metals with smaller particles like W and Cr are favored. However, due to their reactive chemical properties, W and Cr require higher vacuum levels for coating.

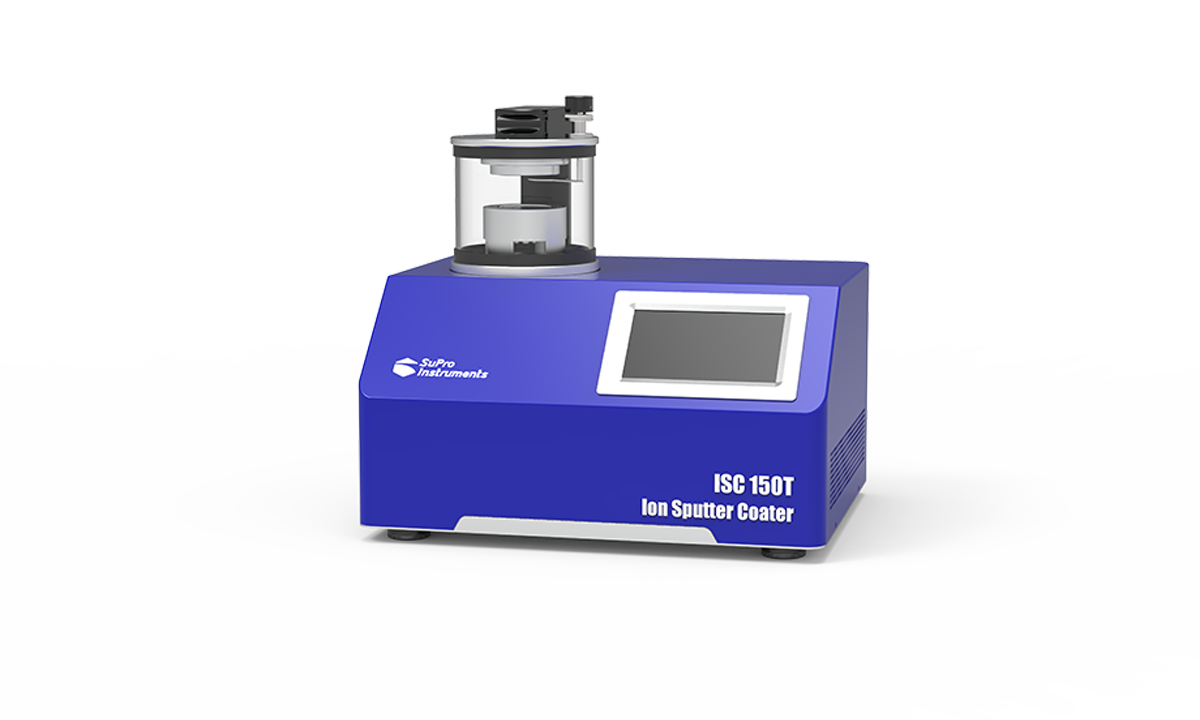

The ISC150T is a high-vacuum ion sputter coater that utilizes a combination of a diaphragm pump and a turbomolecular pump, capable of generating a high vacuum in the range of 10-3 Pa. It can sputter noble metal targets such as Au, Pt, or Pd, as well as easily oxidizable targets such as W, Cr, and C. It is particularly suitable for high-resolution, high-magnification field emission SEM sample preparation.

|

Technical Specifications |

Parameters |

|

Vacuum Pump System |

Oil-free Diaphragm Pump and Turbo Pump |

|

Pumping Speed |

>0.7m3/h ( Diaphragm pump ) + 60 L/S ( Turbo pump ) |

|

Ultimate Vaccum |

<1E-3 Pa |

|

Working Pressure |

0.3-1Pa |

|

Vacuum Gauge |

Pirani Vacuum Gauge |

|

Gas Control |

MFC(50 SCCM Ar) |

|

Chamber |

Ø150 *120mm Scratch-resistant Quartz Glass |

|

Sputtering Target |

Target Dimension Ø 50*0.1-2mm ( Recommended Thickness ≥0.2mm ) Capable of Sputtering Noble Metals like Au, Pt, Pd, as well as Common Materials like Cr, W, C. |

|

Sputtering Power |

Constant Power Magnetron Sputtering DC Power Supply ( Max.30W, Max.100 mA, 0-800V DC ) |

|

Gas Inlet |

Ø8mm Gas Pipe |

|

Operation Mode |

Touchscreen Control with the Control System Providing Interlock Protection Functions |

|

Weight |

~30 Kg |

|

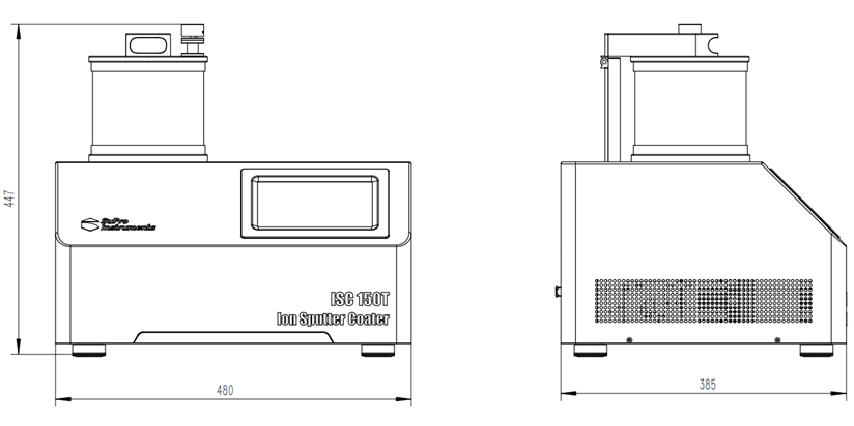

Dimension |

480mm*385mm*447mm |

|

Power Supply |

100-220V AC, 50/60Hz Grounded Three-prong Plug |

|

Power Consumption |

<500 W |

|

Warranty |

One Year |